Industry Standards Met by Optical Fibre Diameter Analyser Systems

Industry Standards Met by Optical Fibre Diameter Analyser Systems

Blog Article

Enhance Your Fiber Optic Projects With an Efficient Size Analyser

The assimilation of a reliable size analyser right into fibre optic jobs offers as a pivotal element in attaining precision and consistency. By helping with accurate diameter measurements, these analysers not just enhance the top quality of installments yet likewise reduce prospective compatibility issues among components. Furthermore, the innovative capacities of contemporary analysers improve information collection and quality control processes. As we explore the crucial attributes and advantages of these devices, it comes to be apparent how they can change job outcomes and make certain adherence to industry criteria. What stays to be talked about is just how to successfully execute these analysers in your existing workflows.

Importance of Diameter Dimension

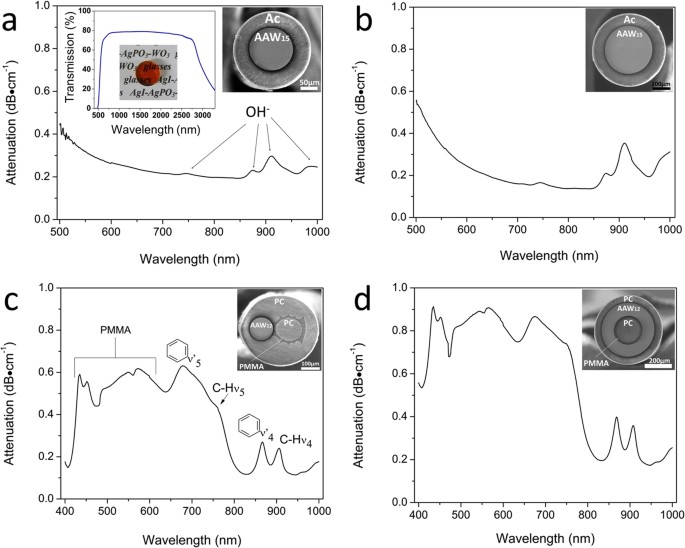

Determining the size of fiber optic wires is a vital task that guarantees optimal performance and reliability in interaction systems. Exact size measurement is vital for different reasons, mainly for preserving signal stability and lessening loss. A cable television's diameter straight affects its capability to transfer light efficiently; discrepancies from the specified size can cause boosted attenuation, which impacts the overall performance of the network.

Furthermore, specific dimension is vital during the installation and upkeep of fiber optic systems. An incorrect fit between wires and connectors can cause signal deterioration or complete failing of interaction links. By guaranteeing that sizes are within specified resistances, service technicians can enhance compatibility in between elements, resulting in better system dependability.

Additionally, size dimension plays a considerable role in top quality control during manufacturing. Uniformity in the size of fiber optic wires is crucial for guaranteeing consistent performance throughout different sets. optical fibre diameter analyser. This uniformity assists suppliers preserve sector requirements and cultivates confidence amongst end-users

Features of an Efficient Analyser

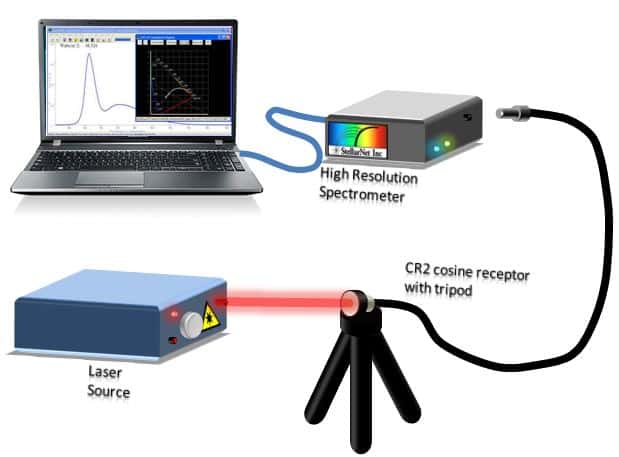

A reliable analyser for fiber optic projects need to incorporate a number of key functions that improve precision and usability in diameter dimension. High-resolution optical sensing units are important for accurate diameter analyses, enabling individuals to discover even the tiniest variants in fiber thickness. These sensing units need to be complemented by sophisticated calibration systems, making certain consistent performance throughout various problems and materials.

Secondly, an user-friendly interface is important for helping with simplicity of operation. This consists of instinctive software that allows for seamless data input and outcome, in addition to aesthetic representations of the measurements taken. A portable design improves use in numerous area settings, making it easier to conduct evaluations on-site.

Furthermore, the analyser needs to sustain multiple measurement settings, fitting various fibre types and applications. The capacity to store and get historic data is an additional vital attribute, permitting customers to track efficiency gradually and make educated choices.

Advantages for Fiber Optic Projects

Carrying out a size analyser in fibre optic jobs provides substantial benefits that significantly boost project efficiency and quality. Among the key benefits is the capability to guarantee precise measurements of fiber size, which is essential for keeping ideal performance in fiber optic systems. Exact size analyses assist in the recognition of inconsistencies that can cause indicate degradation or loss, hence making certain top notch transmission.

Furthermore, the usage of a size analyser improves the top quality control procedure. By automating measurement jobs, job groups can decrease the moment invested in hand-operated evaluations, leading to faster task completion and reduced labour prices. This performance likewise permits even more rigorous screening protocols, causing enhanced item dependability.

In addition, consistency in fibre diameter dimensions promotes compatibility with various other fibre optic elements, reducing the risk of installment errors and improving general system efficiency. The consolidation of a size analyser not only help in keeping market standards yet likewise promotes self-confidence in task deliverables.

Combination Into Existing Workflows

Incorporating a size analyser right into existing operations can substantially enhance the operational efficiency of fibre optic tasks. By effortlessly incorporating this technology, teams can achieve exact measurements that are vital to preserving the honesty and efficiency of fiber optic systems. This integration allows for real-time information collection and evaluation, which can be essential during the production and installment stages.

In addition, the capacity to automate diameter dimension processes decreases the possibility for human mistake, guaranteeing consistent top quality control throughout the project lifecycle. The information try here produced can be easily shared throughout systems, assisting in collaboration amongst designers, professionals, and job managers. This ease of access improves decision-making and speeds up job timelines.

Selecting the Right Diameter Analyser

When picking a size analyser for fibre optic tasks, it is vital to think about special info numerous crucial elements that straight impact dimension accuracy and functional performance. Initially, the resolution and accuracy of the analyser need to straighten with the particular requirements of your task. Greater resolution tools can detect minute variations in size, which is essential for making certain optimum efficiency in fibre optic systems.

For jobs with limited due dates, a size analyser that uses quick information acquisition can significantly boost performance. Furthermore, think about the analyser's compatibility with existing systems and software.

An additional crucial variable is the variety of diameters the analyser can accommodate. By thoroughly assessing these aspects, you can pick a size analyser that improves the effectiveness and precision of your fibre optic projects.

Final Thought

In conclusion, the combination of a reliable diameter analyser is paramount for boosting fiber optic jobs. Accurate diameter measurements make certain optimal efficiency and reliability while lessening installation mistakes (optical fibre diameter analyser).

A cable television's size straight influences its capability to transfer light successfully; inconsistencies from the defined diameter can lead to increased attenuation, which affects the total performance of the network.

Report this page